hftupgfoew

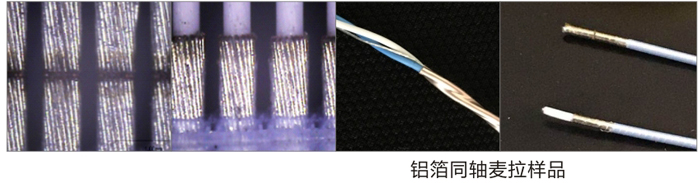

The equipment is used in medical equipment, aerospace, automobile, computer cable and mobile phone cable (HDMI cable, Lightning data cable, Micro data cable, USB3.1Type-c) and other aluminum foil and coaxial Mylar laser.

1. Laser profile is an efficient micromachining process;

2. Non-contact laser laser wire, without damaging the question and core wire;

3. Precise positioning, you can edit the position of the wire arbitrarily to achieve precise positioning;

4. The equipment system is specially designed and developed for front-line operators, simple, easy to understand and easy to operate;

5. High efficiency, fast speed, yield rate of 99.99%, suitable for mass wire processing and production;

6. The equipment has a compact structure, one-button start, simple maintenance, and no consumables;

7. The laser has a service life of up to 100,000 hours and stable performance.

1. Single/multiple can be processed:

① After processing the wire, after the parameters are set, there is no need to adjust it;

② Compared with ordinary laser engraving machine, it has faster speed and higher processing efficiency;

③ With special tooling, the equipment can process multiple wires at one time;

2. Higher quality, high pass rate:

① The thinking machine adopts 360-degree irradiation, which can completely cut off the shielding layer;

② The equipment does not damage the insulating layer and can achieve high accuracy;

③ Processing and production can be carried out by directly setting parameters according to the OD of the wire, and the operation is simple.

3. Compact structure and simple maintenance:

① Small desktop structure (width 280mm x height 500mm x length 750mm);

② The processing area and optical components are completely open, and the processing is flexible and easy to operate;

③ The optical lens does not require daily cleaning and maintenance, and the equipment is maintenance-free and has no consumables;

4. Special equipment, simple operation:

① Customized according to customer needs, can be used independently or with assembly line

② Special specifications can be put into mass production after purchase.

| Index | Parameter name | Parameter |

| Laser parameter | Average output power | 20W x 2(Continuous or pulse) |

| Laser wavelength | 1064nm | |

| Fiber laser | Domestic/imported | |

| Laser method | Four-way splitting | |

| Power adjustment range | 10-100% | |

| Repeat frequency | 20-100KHz | |

| Beam quality | M²<2 | |

| Profile performance | Section line depth | ≤0.4mm |

| Table positioning accuracy | ±0.02mm | |

| Maximum straight cutting speed | 4000mm/s | |

| Move method | Servo motion platform or precision stepping motion platform | |

| Control system | PLC plus touch screen | |

| Laser power supply | Aohua dictatorship | |

| Physical characteristics | Power consumption of the whole machine | ≤1.2KW |

| Electricity demand | 220V±10%/50Hz/5A | |

| Cooling method | Air cooling | |

| Laser lifetime | >100000h | |

| Use environment | Clean and dust-free, no seismic source |

Previous:Laser pipe cutting machine

Next:No data